shop drawings definition engineering

NFPA 13 has specific requirements to what is required for a shop drawing submittal. Shop drawings ARE for construction.

What Is Shop Drawings Why Is It Important

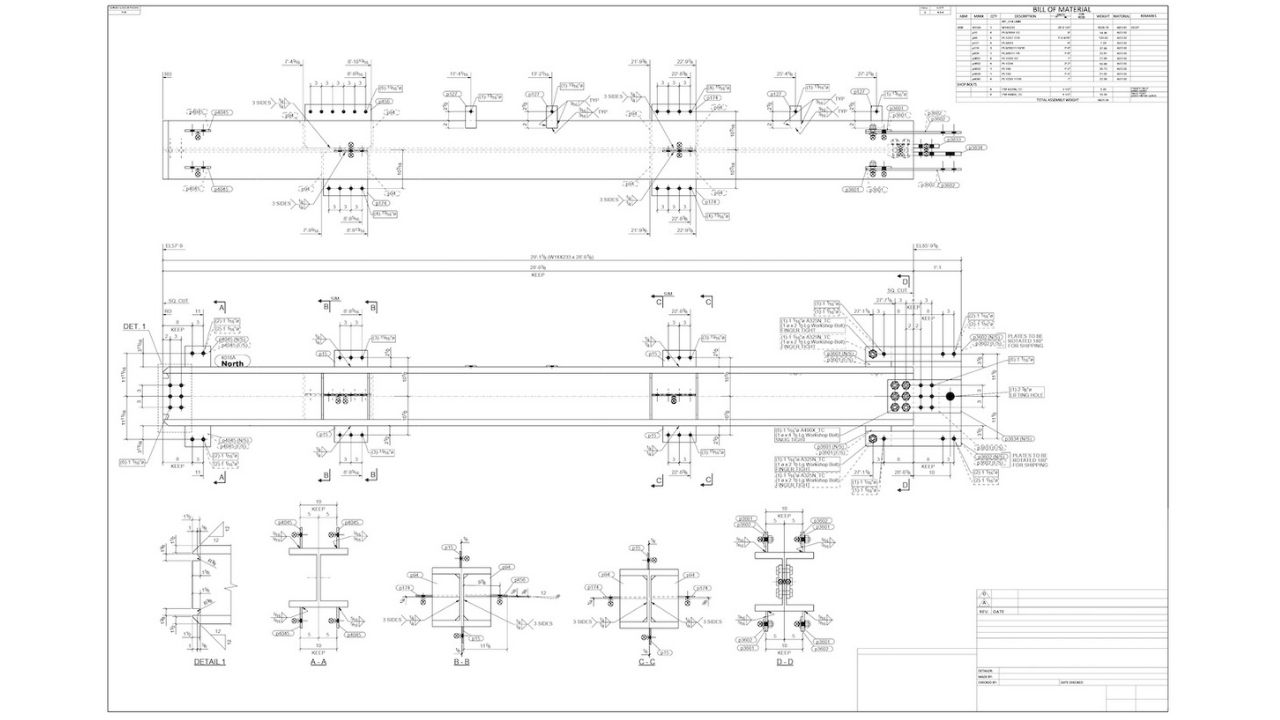

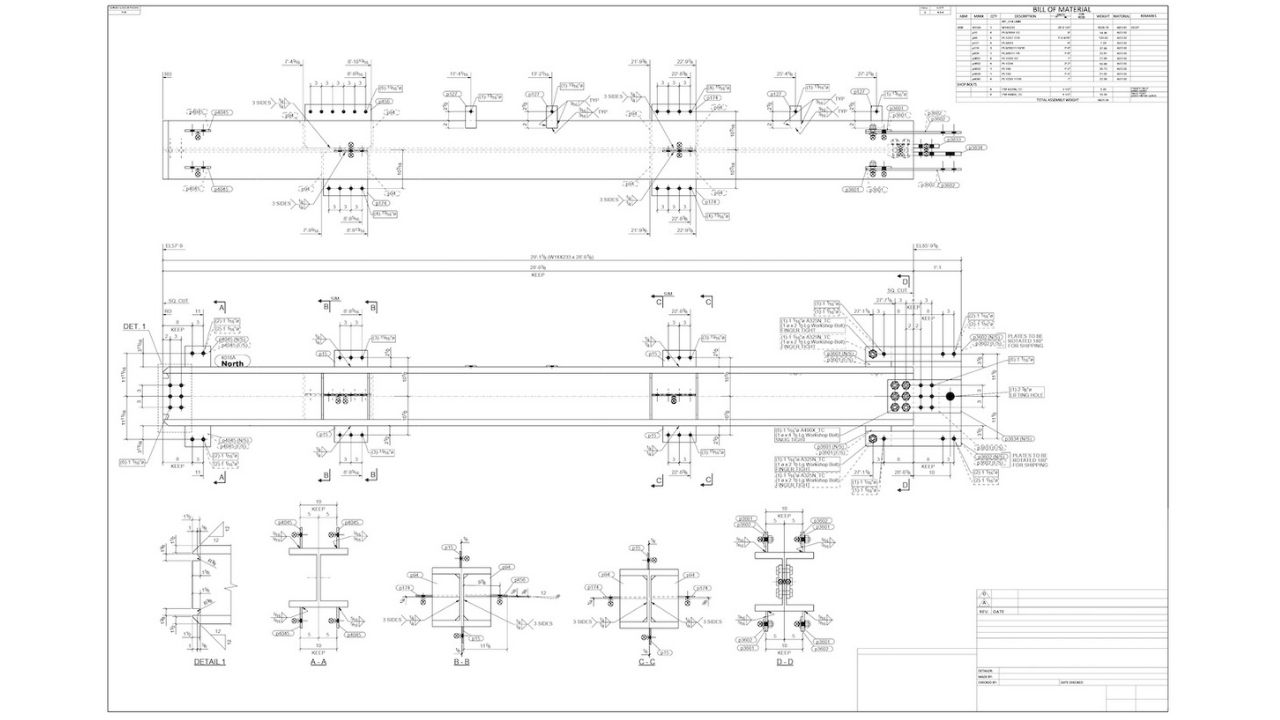

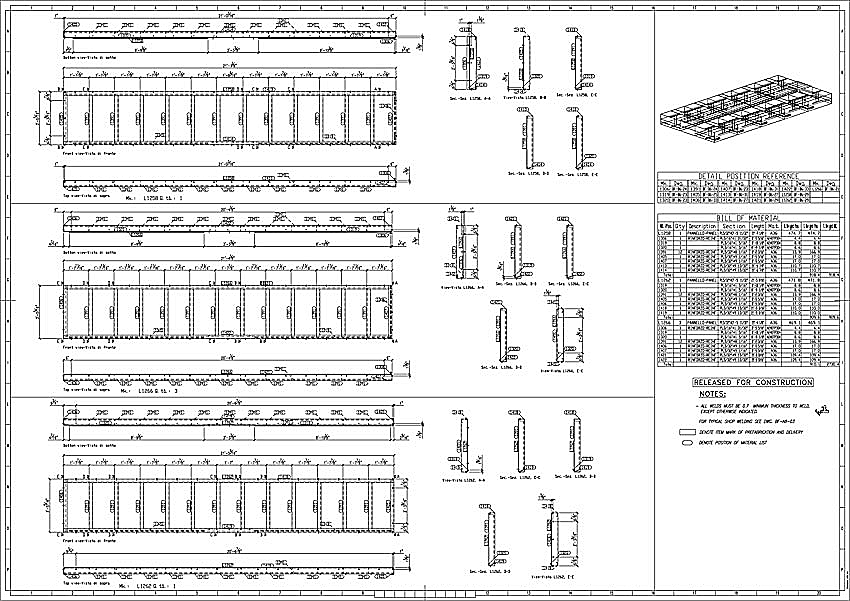

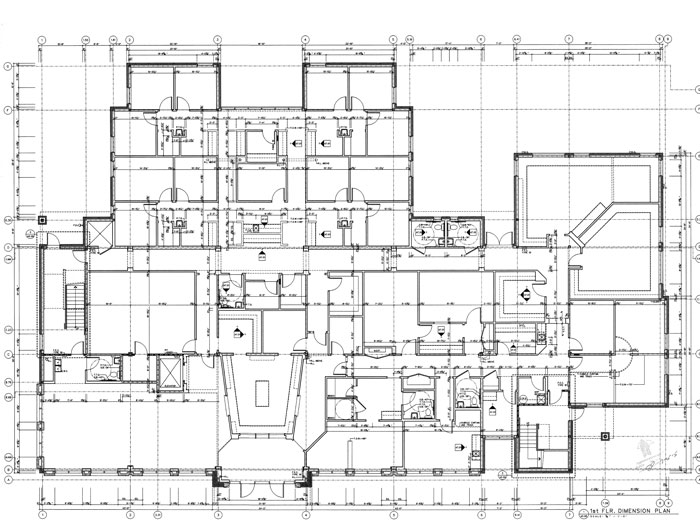

Shop Drawings means drawings submitted to the PHA by the Contractor subcontractor or any lower tier subcontractor showing in detail 1 the proposed fabrication and assembly of structural elements and 2 the installation ie form fit and attachment details of materials of equipment.

. Are there any other parties that will be involved in the shop drawing review process. Theyre developed by contractors after theyve signed a contract with the Owner and are commencing work even if. Engineering drawings use standardised language and symbols.

It is enforceable by the Authority Having Jurisdiction anywhere that NFPA 13 is used as the reference standard. Design drawings are part of the official documents for approval to commence. They are also required for prefabricated components.

A shop drawing is a drawing or set of drawings produced by the contractor supplier manufacturer subcontractor consultants or fabricator. Submittals which include shop drawings and other administrative documents are how the contractor. Shop drawings are developed by or on behalf of a contractor that will be performing work on the project.

Ad On time On budget Accurate Shop Drawings by Shop Drawing Services Ltd. But the only thing that contractors really want to know is that it is OK to proceed as indicated on the submittal. They generally relate to pre-fabricated components showing how they should be manufactured or installed.

Shop drawings are prepared following a review of the drawings specifications and contract documents supplied by the registered professional of record and other project consultants as. Engineers should not accept submittals directly from a subcontractor or vendor. Under sections 3126 and 3127 of AIA A201 the contractor must review and approve shop drawings before sending them to the architect or engineer.

Element set forth in the shop drawing. Shop drawings are typically required for prefabricated components. What items require shop drawings.

Examples of these include. Also critical are the installation and c. They are drawn to explain the fabrication andor installation of the glazing items for the manufacturers.

Elevators structural steel trusses pre-cast concrete windows appliances cabinets air handling units and millwork. Shop drawings are typically required for prefabricated components while Design Drawing are the preliminary drawing which could be sketch or pattern aimed for the specific purpose. We provide Professional Shop Drawings ServicesYour Shop Drawing ready on time.

Below is a basic checklist for items that are required to be indicated in a shop drawing package with references to whichever edition of NFPA 13 is. Shop drawings are typically required for prefabricated components. Engineering drawings support on-site contractors while manufacturing drawings assist off-site contractors.

Shop drawings are prepared by fabricators suppliers equipment manufacturers sub-contractors and contractors or by others retained by these parties. The American Institute of Architects AIA family of contracts defines shop drawings as drawings diagrams schedules and other data specially prepared by a distributor supplier manufacturer subcontractor or contractor to show some part of the work. This bypasses the general contractors opportunity to review drawings for coordination.

Shop Drawing or field drawing means a drawing prepared by a contractor subcontractor or vendor that shows how a particular aspect of the work is to be fabricated and installed and demonstrates how an aspect of the work will satisfy the requirements of the construction document but does not include a final drawing specification survey plat plate report or other. What Are Shop Drawings. A shop drawing is a drawing set of drawings produced by the contractor check Examples of these include.

They provide fabricators with the information necessary to manufacture fabricate assemble and install all the components of a structure. They typically include plans elevations views sections and several other details. Shop drawings also known as fabrication drawings are detailed plans that translate design intent.

Elevators structural steel trusses pre-cast windows appliances cabinets air handling units and millwork. When are the shop drawings to be provided to the design professional for review and approval. Engineers review shop drawings to increase the likelihood that defects or deficiencies in the contractors submittals can be identified before offending equipment or systems are installed.

The purpose is to convey all the information necessary for manufacturing a product or a part. This time in the Knowledge Series we will discuss the difference between manufacturing drawing and engineering drawing. The AEC industry tends to use these terms interchangeably when in fact they are distinct from each other.

The shop drawings are drawn to show the Glazing Contractors or the manufacturers actual product information that is specified in the architects construction documents. Examples of these include. The drawings normally show more specific details than the architectural construction documents.

An engineering drawing is a subcategory of technical drawings. Shop drawings or working drawings can be hand drawn to describe a cross section or plan. Shop drawings also known as fabrication drawings are detailed plans that translate design intent.

Who is responsible for preparing the shop drawings. They provide fabricators with the information necessary to manufacture fabricate assemble and install all the components of a structure. Shop drawings - Designing Buildings - Share your construction industry knowledge.

Shop drawings also known as technical drawings are drawings or sets of drawings created by fabricators contractors subcontractors manufacturers or suppliers. What are Shop Drawings. A shop drawing is a drawing or set of drawings produced by the contractor supplier manufacturer subcontractor or fabricator.

A shop drawing is basically a scale drawing that includes comprehensive information about prefabricated components of designed structures along with detailed information about associated components assembly of different parts fabrication material types component shape size color installation procedure of various units and other. Shop drawings or workshop drawings might be prepared by contractors subcontractors suppliers manufacturers or fabricators. This makes understanding the drawings simple with little to no personal interpretation possibilities.

Elevators structural steel trusses pre-cast concrete windows appliances cabinets air handling units and millwork.

Shop Drawings Definition Use Examples Software Alternatives

Mep Shop Drawings What Are They And What Are Their Benefits

The Difference Between Design Drawings And Shop Drawings

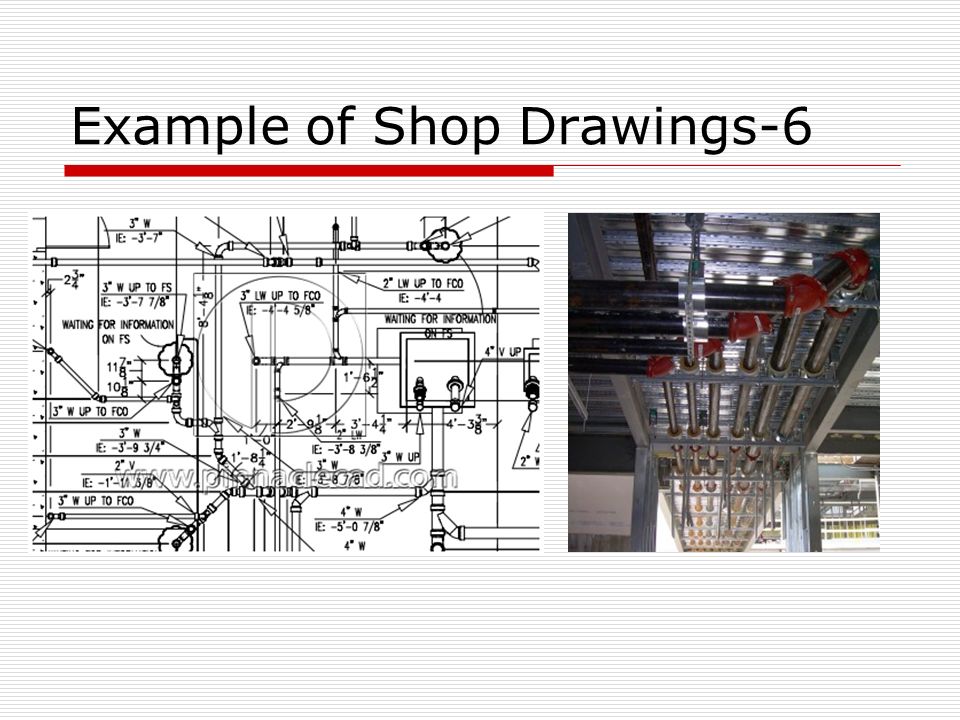

Cve 4070 Construction Engineering Shop Drawings Quality Control Ppt Video Online Download

Shop Drawings Of Construction Project I Type Of Shop Drawings Iram Hameed Rather Youtube

Difference Between Shop Drawings And As Built Drawings

Shop Drawings Designing Buildings

Electrical Shop And Fabricatrion Drawings Advenser

Shop Drawings Vs Submittals Youtube

As Built Drawings And Record Drawings Designing Buildings

Electrical Shop And Fabricatrion Drawings Advenser

Mep Shop Drawing Detailing Services Fulfill The Needs Of Mechanical Electrical And Plumbing Structural Engineering Diagram Architecture Shop Window Design

Shop Drawings Vs As Built Drawings Bimex

What Is Engineering Drawing Different Types Of Lines In Engineering Drawing Cnclathing

Shop Drawings Definition Use Examples Software Alternatives

Shop Drawings Definition Use Examples Software Alternatives

Asme Standards For The Revision Of Engineering Drawings Owlcation